Is your commercial building project in need of overhead doors? Choosing the best commercial overhead door for your facility can be tough because there are many types to consider. From rolling steel doors to aluminum full-view designs, each type has unique uses. They offer different benefits, limitations, and price ranges.

At Doorvana, we’ve helped commercial general contractors and property developers in North Texas outfit their buildings with overhead doors. We answer questions that other door companies avoid. This includes tough topics like pricing, drawbacks, and when you don’t need the most expensive option. Our job is to identify any “gotchas” early in your project so that when the doors arrive, installation proceeds without delay.

When selecting overhead doors for new buildings or replacing existing ones on a commercial site, it’s essential to understand your options. This helps you make a wise choice.

In this article, we’ll cover:

- The different types of commercial overhead doors on the market

- Key factors used to determine the best door type for your facility

- The top 5 commercial overhead door types ranked by investment level

- Detailed advantages and disadvantages of each door type

- Price ranges for 10’x10′ openings (excluding tax and installation)

- Actual project examples from North Texas installations

By the end of this article, you’ll know which commercial overhead door type suits your project needs, budget, and long-term goals.

Let’s get started.

Understanding Commercial Overhead Door Categories

Commercial overhead doors come in two main types, each designed for different uses:

Rolling Doors (Coiling Doors)

Rolling doors feature interlocking steel slats or sheets that coil around a barrel or drum positioned above the opening. When the door opens, these slats roll tightly into a compact coil. Unlike sectional overhead doors, rolling doors cannot be mounted in various positions. They must be mounted just above the opening.

Rolling doors work well in busy places like factories, parking garages, and storage units. Here, security and durability matter more than visibility or natural light. They’re the workhorse of the commercial door industry—designed to take a beating and keep performing year after year.

Sectional Overhead Doors

Sectional doors consist of horizontal panels (typically 18″-24″ tall) connected by hinges. These panels travel upward and then horizontally along overhead tracks. Sectional doors are versatile. They can include windows or full-view glass panels.

Sectional doors are ideal for projects where appearance is important. They are also great for temperature control and when natural light and visibility are top priorities. They are often used in auto dealerships, modern industrial sites, and restaurants with open kitchens. These doors enhance the look of any customer-facing space.

Key Differences

-

Rolling doors come in a wider variety of sizes.

-

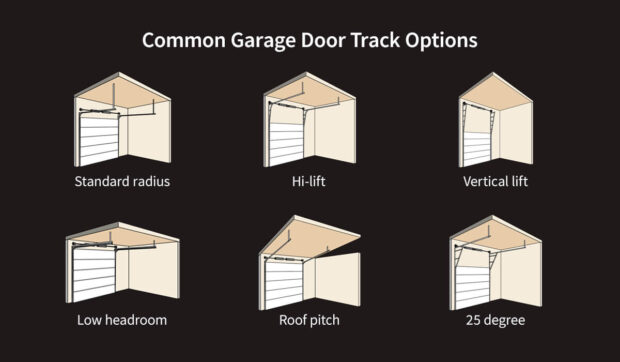

Sectional doors can be installed many ways, from standard to vertical lift, or to follow the roof-pitch. Rolling doors can only be mounted directly above the door opening.

-

Rolling doors offer limited designs and typically feature a horizontal slat or plank design.

- Both require maintenance, but sectional doors are typically less expensive and easier to maintain or repair.

6 Key Factors to Determine the Best Commercial Overhead Door

Before diving into specific door types, let’s examine the factors that should drive your selection process:

1. Usage Frequency and Cycle Requirements

How many times per day will your door operate? A door that opens five times daily has vastly different requirements than one that cycles 50 times or more daily.

Commercial overhead doors are rated by cycle count—one complete open and close sequence equals one cycle. Standard sectional commercial doors usually have a warranty for 25,000 cycles. This means they can last about 10 to 15 years in moderate-use situations. You can always request or explore higher cycle doors that range from 50,000 to 100,000 cycles.

When choosing doors for a busy loading dock, distribution center, or parking area, knowing the cycle requirements is key. This helps avoid early failures and surprise replacement costs.

2. Security and Protection Needs

Different facilities have different security requirements. A self-storage facility needs theft deterrence. A parking garage needs basic security. A dispensary or high-value retail location needs forced-entry resistance.

Rolling doors generally provide superior security compared to sectional doors. The interlocking slat design makes them hard to break through. Also, the compact coiling mechanism removes the pivot points found in sectional doors at each panel joint. For maximum security applications, heavy-gauge steel construction and reinforced locking mechanisms are essential.

3. Environmental Conditions

North Texas weather isn’t as extreme as hurricane zones or northern areas, but environmental factors still play a role:

Temperature Control: Does your facility require climate control? Insulated doors significantly reduce energy costs by minimizing heat transfer. R-values ranging from 6 to 15+ are available depending on insulation type (polystyrene vs. polyurethane). Rolling doors are inherently less efficient than sectional doors.

Weather Sealing: Quality commercial overhead doors have seals at the perimeter, top, and bottom. These seals keep rain and debris out. Some installations can be tricky. For example, buildings without drip ledges need thicker bottom seals. This helps stop water from getting in.

Wind Loads: Most North Texas projects use Windcode 0 or 1. However, facilities in exposed areas might need higher wind-load ratings.

Corrosive Environments: If you’re near the coast, exposed to chemicals, or need wash-downs, stainless steel parts or special coatings may be necessary.

4. Speed and Operational Efficiency

How quickly does your door need to open and close? Standard commercial doors operate at conventional speeds suitable for most applications. High-traffic facilities gain from quicker cycle times. This boosts productivity, improves security by keeping doors open less, and lowers HVAC load from air exchange.

5. Visibility and Aesthetic Requirements

Does your door face customers? Does your facility need natural light? Is architectural design a factor?

For customer-facing spaces like auto dealerships, restaurants, and modern industrial areas, a door is more than just a functional feature. It’s a key part of your building’s design. Full-view aluminum doors with glass panels add a sleek, modern style.

For back-of-house loading docks or industrial warehouses, aesthetics take a back seat to durability and value.

6. Budget and Total Cost of Ownership

Commercial overhead doors represent a significant investment, but the cheapest upfront option isn’t always the most economical long-term choice.

Consider the total cost of ownership:

-

Initial investment: Door purchase and installation.

-

Expected lifespan: How many years before replacement?

-

Maintenance requirements: What’s needed to keep the door operating properly?

-

Energy impact: For climate-controlled facilities, insulation pays dividends.

-

Downtime costs: A failed door can shut down operations—what’s that worth?

We don’t claim to be the cheapest at Doorvana. Our pricing shows the value of skilled technicians, quality tools, and reliable service. We are a company built to last for generations. The question isn’t “what’s cheapest?” but rather “what’s best”?

Top 5 Commercial Overhead Door Types

Here are the four most common types of commercial overhead doors, ranked by initial investment from highest to lowest. For each type, we’ll examine common uses, main features, pros and cons, and real-world prices for a standard 10′ x 10′ opening.

Important Pricing Note: All prices shown exclude sales tax and installation labor. Prices reflect standard configurations with a standard lift. The price excludes options like alternative tracks, operators, or hardware upgrades.

Key Pricing Influences:

-

Overall size: Height triggers a larger price increase than width.

-

Track type: High-lift, vertical-lift, and follow-the-roof pitch tracks are more than standard lifts.

-

Ceiling height: Taller ceilings require more material and increased labor costs for installation.

-

Modern office and industrial spaces: Support contemporary architectural design with abundant natural light

-

Fitness centers: Provide natural lighting for workout areas while enabling flexible space configuration

-

Fire stations: Allow visibility of apparatus while protecting equipment from elements

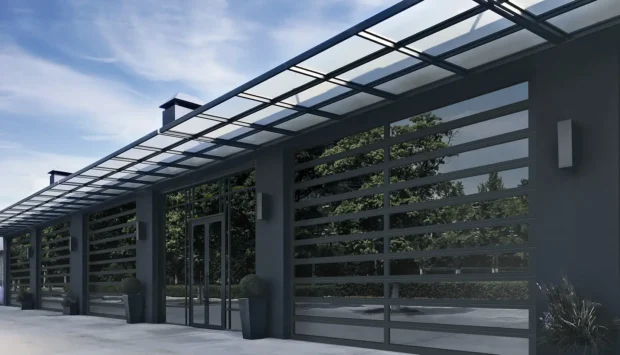

Door Type #1: Full-View Doors

Representative Product: Clopay 904 Aluminum Full-View Typical 10’x10′ Investment: $7,500 – $11,500 (door only, excluding tax and installation)

What Are Full-View Doors?

Full-view doors are sectional overhead doors featuring aluminum frames with full-vision glass panels. These doors let in plenty of natural light and visibility. They also provide security and weather protection of a commercial overhead door. The aluminum build resists corrosion and needs little upkeep. The glass panels add a modern, open look.

The Clopay 904 series stands out in this category. It features non-insulated construction and comes in a black anodized acid-etched finish. You can also find ⅛” tempered clear glass and torsion spring operation. It has a 3″ full tapered track with a standard lift configuration.

Best Applications

Full-view doors excel in environments where appearance and natural light are paramount:

-

Auto dealerships and service centers: Display cars and service areas while keeping climate zones separate.

-

Restaurants and breweries: Link dining areas with exhibition kitchens or brewing operations visually.

-

Modern office and industrial spaces: Support contemporary architectural design with abundant natural light

-

Fitness centers: Provide natural lighting for workout areas while enabling flexible space configuration

-

Fire stations: Allow visibility of apparatus while protecting equipment from elements

Key Features

Aluminum Frame Construction: Extruded aluminum is strong but lightweight. It needs less maintenance than steel. Anodized finishes, especially black and clear, are popular in North Texas. They resist fading and corrosion better than painted finishes.

Glass Panel Options: Standard ⅛” tempered clear glass provides basic visibility and impact resistance.

Upgraded options are:

-

Insulated glass units

-

Tinted or shaded glass

-

Argon-filled panels for better thermal performance

Customization Options: Choose from various aluminum finishes, glass types, and panel configurations. Track systems accommodate standard, high-lift, or vertical-lift requirements. Torsion springs are available in 25,000, 50,000, or 100,000-cycle ratings depending on expected usage.

Weather Sealing: Quality full-view doors have full perimeter weather sealing. This prevents air and water from getting in, even with glass panels.

Advantages of Full-View Doors

Stunning Curb Appeal: A full-view aluminum door offers a sleek, modern look that stands out. These doors create a design statement for customer-facing facilities. Sectional steel doors can’t match that impact.

Natural Light: Less indoor lighting saves energy, especially in big buildings with many doors. Natural light also creates a more pleasant work environment.

Aluminum Durability: Unlike steel, aluminum doesn’t rust. The anodized finish is baked into the metal, rather than being just a coating. This makes it much more resistant to scratching, chipping, and fading than painted surfaces.

Visibility and Safety: Operators can look through the door before opening it. This reduces the risk of collisions and enhances situational awareness.

Brand Alignment: For businesses where the building is part of the brand—like high-end auto dealers or trendy restaurants—full-view doors support a premium image. The Fort Worth Tesla dealership has multiple full-view doors throughout the building.

Disadvantages of Full-View Doors

Premium Investment: Full-view doors are the most expensive option on a per-square-foot basis. The price for a 10′ x 10′ opening ranges from $7,500 to $11,500, making these doors quite expensive.

Thermal Performance: Non-insulated full-view doors provide minimal thermal resistance. Insulated glass units are available, but they are more expensive.

Glass Maintenance: Regularly clean glass to maintain its appearance. This is especially important in dusty industrial settings or places near roads. Tempered glass resists impact, but it can break under strong force.

Privacy Concerns: Even with obscure glass, you can view objects behind the doors.

Pricing Factors for Full-View Doors

The $7,500-$11,500 range for a 10’x10′ full-view door reflects several variables:

-

Frame Finish: Anodized finishes (black, clear) are better than painted ones in North Texas. They last longer and are more durable.

-

Glass type: Standard is single-pane tempered glass. Insulated, shaded, or argon-filled glass increases the cost.

-

Track configuration: High-lift or vertical-lift tracks cost more than standard lift tracks

-

Track size: 3″ track systems cost more than 2″ systems

-

Framing material: Your building material may determine the track type need

-

Hardware cycles: 50,000 or 100,000-cycle springs and hardware command premium pricing over 25,000-cycle components

When to Choose Full-View Doors

Full-view doors are the right choice when:

-

Your facility faces customers, and its appearance directly impacts business

-

Natural light is a priority for operations or energy efficiency

-

Contemporary architectural design is part of your building’s identity

-

Visibility through the door provides operational or safety benefits

-

Budget accommodates the premium investment

-

The door opening isn’t in a maximum-security application

As one general contractor told us after we installed full-view doors at an auto dealership: “The doors cost more, but they’re part of what makes this facility feel premium. Customers notice.”

Door Type #2: Rolling Service Doors

Representative Product: Clopay CESD10 Typical 10’x10′ Investment: $6,000 – $9,000 (door only, excluding tax and installation)

What Are Rolling Service Doors?

Rolling service doors represent the commercial-grade tier of coiling steel doors. Rolling service doors are different from basic rolling sheet doors. They use heavier-gauge steel, stronger mechanisms, and last much longer. These doors are designed for use in tough commercial and industrial settings. Here, reliability and security are key.

The steel slats wrap around a barrel above the door. This design requires minimal headroom, which is a significant advantage for many commercial spaces. The CESD10 fits this category well. It has a robust build, making it ideal for daily use in demanding environments.

Best Applications

Rolling service doors are the workhorses of commercial facilities:

-

Parking structures: Where security, weather protection, and space efficiency converge

-

Loading docks: Securing receiving areas when not actively loading/unloading

-

Self-storage facilities: Providing tenant security with minimal maintenance requirements

-

Warehouses and distribution centers: Interior and exterior openings requiring security

-

Manufacturing facilities: Separating production areas or securing equipment rooms

-

Retail back-of-house: Securing storage areas and receiving docks

-

Service centers: Truck service centers and heavy equipment facilities

Key Features

Heavy-Gauge Steel Construction: Commercial-grade rolling service doors use thicker steel than economy rolling sheet doors. The heavier gauge offers better impact resistance, improved wind-load performance, and a longer service life.

Minimal Headroom Requirements: The compact coiling mechanism needs less headroom than sectional doors. This advantage is key for places with low ceilings or buildings that need high lifts for forklift access.

Multiple Operating Options: Rolling service doors are compatible with various operators. You can use a chain hoist, a manual push-up for smaller doors, or motor operators with various controls.

Sizes and Configurations: Rolling service doors are available in a wide range of sizes. While there’s no single “standard” size, common installations range from 8′-30′ wide by 8′-16′ tall. Larger sizes are available for specialized applications.

Cycle Ratings: Commercial rolling service doors come with warranties of 25,000, 50,000, or 100,000 cycles. Choose based on how much your facility uses them.

Advantages of Rolling Service Doors

Superior Security: The interlocking slat design makes rolling doors hard to break into. This is better than sectional doors, which have many panel joints. For high-security applications, rolling service doors are often the first recommendation.

Space Efficiency: Rolling service doors need less headroom. This makes them perfect for tight spaces or areas that want to utilize their interior height more effectively. This is especially useful in parking structures and warehouses. Every foot of vertical clearance is important.

Durability and Longevity: Heavy-gauge steel construction withstands impacts, wind loads, and years of daily operation. Commercial-grade rolling service doors routinely deliver 15- 20+ years of service in demanding environments.

Insulation Options: Most rolling doors are non-insulated. However, if you need temperature control, insulated rolling service doors are also available. Insulated slat options offer solid R-values. They also keep the security and space-saving benefits of rolling construction.

Smooth Panel Options: Smooth-panel rolling doors are growing in popularity. They look cleaner than traditional corrugated doors. Plus, they don’t compromise on performance.

Low Maintenance: Rolling service doors have fewer moving parts than sectional doors. They also lack panel joints, which means less ongoing maintenance is needed. The simple, robust design means fewer service calls over the door’s lifetime.

Disadvantages of Rolling Service Doors

Limited Visibility: Rolling doors block all sight unless they have vision panels or perforated slats. You can’t see through the door, which can be a safety issue. This may also be a problem if natural light is essential.

Standard Operating Speed: Rolling service doors run at typical commercial speeds. They work well for most uses but can be slower than sectional doors. If cycle time is critical to operations, this can impact productivity.

Aesthetic Limitations: Despite smooth panels and custom colors, rolling doors still appear industrial. For customer-facing applications that require a contemporary design, rolling doors may not convey the desired image.

Noise: Rolling doors generate more noise during operation than well-maintained sectional doors, although they aren’t particularly loud. In noise-sensitive environments, this can be a consideration.

Repair Complexity: When rolling door parts fail, especially the coil mechanism or barrel assembly, repairs need special knowledge and tools. While the doors are reliable, when they do need service, it’s not a DIY repair.

Real-World Application: Parking Structure

We ordered an Amarr 4000 Series Rolling Steel Service Door (14’6″ wide by 14′ tall) for a parking facility in Dallas, with an approximate investment of $15,000. The project needed a sturdy door. It had to manage daily use and maintain the parking area’s security.

The Amarr 4000 series is the industry standard, providing excellent security and years of worry-free operation. The rolling door’s minimal headroom requirement was critical in this application, as the parking structure’s ceiling height was limited. A sectional door would have required additional structural modifications to accommodate the track system, increasing project costs significantly.

Pricing Factors for Rolling Service Doors

The $6,000-$9,000 range for a 10’x10′ rolling service door reflects these variables:

-

Steel gauge and thickness: Heavier gauge steel costs more but provides better durability and wind-load resistance

-

Insulation: Insulated rolling doors command significant premiums over non-insulated models

-

Finish options: Custom colors, smooth panels, or specialized coatings increase cost

-

Operating mechanism: Chain hoist systems cost more than manual operation; motor operators add substantial expense

-

Hood and weather protection: Protective hoods around the coil mechanism and enhanced weather sealing affect pricing

-

Cycle rating: 50,000 or 100,000-cycle components cost more than standard 25,000-cycle ratings

When to Choose Rolling Service Doors

Rolling service doors are the right choice when:

-

Security is a top priority

-

Headroom is limited or maximizing interior height is important

-

Multiple doors will be installed in close proximity

-

Durability and long service life matter more than aesthetics

-

The door location is interior or back-of-house where appearance is secondary

-

Budget supports commercial-grade construction but doesn’t require premium features

-

Natural light and visibility through the door aren’t required

Rolling service doors are perfect for many businesses. They offer strong performance, security, and long-lasting use. Their mid-to-upper price is worth the value you get.

Door Type #3: High-Performance Doors

Representative Product: Extreme Series EX3220 Typical 10’x10′ Investment: $3,500 – $5,000 (door only, excluding tax and installation)

What Are High-Performance Doors?

High-performance doors are strong sectional doors designed for durability and low maintenance. They have thicker panels, strong joints, robust hardware, and great weather sealing. These features increase the door’s lifespan and lower ownership costs.

The Extreme Series EX3220 showcases this type with 2″ thick panels, polystyrene insulation, a clean flush design, an R-value of 9.1, and a tongue-and-groove joint system for better weather resistance.

Best Applications

High-performance doors are ideal for facilities where reliability is key:

-

Distribution centers and warehouses: Door failures can disrupt shipping.

-

Manufacturing facilities: Separate production areas while controlling the environment.

-

Cold storage facilities: Insulation and sealing are crucial.

-

Food processing plants: Need sanitary, easy-to-clean surfaces.

-

Commercial garages: Ideal for auto service and fleet maintenance.

-

High-cycle applications: For facilities with 20+ door cycles daily.

Key Features

2″ Thick Panel Construction: Thicker panels offer better insulation, impact resistance, and wind-load performance. They also reduce noise and door flexing. Polystyrene Insulation: Provides good thermal performance at lower costs. The R-9.1 rating suits most Texas applications. Tongue-and-Groove Joint Design: This design enhances weather sealing and reduces air infiltration. It also aligns panels better to prevent separation under wind load. Flush Panel Appearance: The smooth design looks professional and is easy to maintain. Enhanced Hardware: Upgraded hinges, rollers, and track systems extend life and reduce maintenance.

Advantages of High-Performance Doors

Extended Service Life: These doors can last over 20 years, while standard ones last 10-15 years.

Superior Weather Resistance: The thick panels and sealing protect against wind, rain, and temperature extremes.

Reduced Maintenance Requirements: Fewer service calls mean lower costs over time. Improved Energy Efficiency: The R-9.1 insulation and sealing reduce HVAC loads, saving energy.

Quiet Operation: Thicker panels and better rollers make for quieter operation, important in noise-sensitive areas.

Impact Resistance: Thicker panels withstand damage from equipment better, reducing downtime. Versatility: These doors fit various track configurations and can include windows.

Disadvantages of High-Performance Doors

Not True High-Speed Doors: These are conventional doors with standard speeds. For rapid-cycle needs, true high-speed doors are required.

Premium Over Standard Sectional Doors: Higher costs may not be justified for some applications.

Heavier Installation Requirements: The heavier panels need stronger tracks and may increase installation costs.

Overkill for Low-Traffic Applications: For doors that cycle infrequently, standard doors may suffice.

Real-World Consideration: When is High-Performance Worth It?

Choose high-performance doors when cycle frequency and environmental demands are high. For facilities with 20 or more cycles daily, the durability and maintenance savings justify the cost. In climate-controlled spaces, the insulation pays off. For low-traffic areas, standard doors provide adequate performance at a lower price.

Pricing Factors for High-Performance Doors

The $3,500-$5,000 price range is influenced by:

-

Panel thickness and insulation type: 2″ panels with polystyrene are standard; polyurethane increases costs.

-

Track system: Standard lift is included; high-lift or vertical-lift options raise costs.

-

Hardware cycle rating: Standard vs. extended-cycle components.

-

Finish options: Standard white is included; custom colors add costs.

-

Window configuration: Solid panels are standard; windows increase pricing.

-

Operator selection: Options vary from chain hoist to motor operators.

When to Choose High-Performance Doors

Opt for high-performance doors when:

-

Door cycles 20+ times daily and reliability is key.

-

Climate control and energy efficiency are important.

-

Quiet operation is needed.

-

The door faces frequent traffic.

-

Long-term costs are more important than initial investment.

-

Reduced maintenance is a goal.

-

Enhanced weather resistance is required.

For contractors and developers, high-performance doors offer great value. Spending a bit more now leads to better long-term performance and lower operational costs.

Door Type #4: Insulated Sectional Doors

Representative Product: Clopay 3717 Energy Series Typical 10’x10′ Investment: $3,500 – $5,000 (door only, excluding tax and installation)

What Are Insulated Sectional Doors?

Insulated sectional doors focus on thermal performance and energy efficiency. They have foam insulation between steel skins, creating a thermal barrier that limits heat transfer. This results in improved climate control and lower HVAC costs.

The Clopay 3717 Energy Series has 1¾” Intellicore insulation and an R-16.2 thermal rating. It’s made from 27-gauge steel and has a stucco embossed finish. Plus, it includes full weather sealing. This door is designed for environments where temperature control is crucial.

Best Applications

Insulated sectional doors are ideal for climate-controlled spaces:

-

Warehouses with temperature-sensitive products: Protects inventory from fluctuations.

-

Light industrial facilities: Worker comfort and energy savings are priorities.

-

Automotive service centers: Maintains comfortable temperatures for vehicle entry.

-

Distribution centers: Separates conditioned areas from the outdoors.

-

Retail back-of-house: Balances climate control between public and storage.

-

Commercial garages: Any garage needing heating or cooling.

Key Features

Intellicore Polyurethane Insulation: This foam expands inside the door panel. It improves adhesion, fills air gaps, and boosts thermal performance. R-16.2 Thermal Rating: Higher R-values mean better insulation. The 3717’s R-16.2 is excellent for commercial use. 27-Gauge Steel Construction: The durable steel ensures long-lasting performance.

R-16.2 Thermal Rating: The R-value shows thermal resistance. Higher numbers mean better insulation. The 3717’s R-16.2 rating represents excellent insulation for commercial applications. In comparison, non-insulated doors typically rate R-0 to R-3, while high-end residential doors may reach R-18 to R-20.

27-Gauge Steel Construction: The 27-gauge steel skins are durable and keep the door lightweight. Thicker 24-gauge steel is offered for tougher jobs. It costs more and needs stronger hardware.

Thermally Broken Design: The Intellicore insulation forms a thermal break between the inner and outer steel layers. This stops condensation problems that often affect poorly insulated doors in climate-controlled spaces.

Stucco Embossed Finish: This textured finish adds visual appeal. It also hides minor dings and scratches better than smooth surfaces. The micro groove detail adds contemporary styling suitable for visible installations.

Comprehensive Weather Sealing: Quality insulated doors have seals on all four sides—top, bottom, and both jambs. They also seal between panel sections. This complete perimeter sealing system is crucial for realizing the full energy-efficiency benefits.

Advantages of Insulated Sectional Doors

Excellent Energy Efficiency: The R-16.2 insulation cuts down heat transfer through the door. For climate-controlled facilities, this translates directly to lower HVAC costs. In large warehouses with multiple door openings, annual energy savings can be significant.

Reduced HVAC Load: Insulated doors cut down temperature transfer. This means your HVAC system works less. This not only lowers energy costs but also extends HVAC equipment life by reducing run time.

Improved Worker Comfort: For facilities where personnel work near door openings, insulated doors create more comfortable conditions. In summer, they keep cool air in. In winter, they prevent cold drafts.

Condensation Prevention: The thermally broken design prevents condensation from forming on the interior door surface—a common problem with non-insulated doors in air-conditioned spaces. Condensation leads to rust, dripping water, and slippery floors.

Noise Reduction: The insulated panels dampen exterior noise and reduce operational sound. For facilities near busy roads or in quiet zones, this acoustic benefit is as important as thermal performance.

Structural Strength: The Intellicore process forms a composite structure. The foam bonds to both steel skins. This makes the panel stronger and more dent-resistant than hollow or air-filled doors.

Rust Resistance: The galvanized steel construction with quality paint finish resists rust and corrosion. For facilities with high humidity or exposure to moisture, this durability is essential.

Real-World Application: Fort Worth Industrial Park

We just finished a big project for Brazos Development Group at a Fort Worth Industrial Park. We installed twenty Clopay 3717 insulated sectional overhead doors. Each door measures 12’2″ wide by 12′ tall, with a total investment of about $130,000.

The project needed strong doors for commercial and industrial buildings. Temperature control, energy efficiency, and durability were all key factors. The clean, ribbed stucco panel design looked great for the project. Also, the thermally broken design with foamed-in-place polyurethane insulation met the energy needs perfectly.

One challenge we overcame was the building design’s lack of drip ledge above the door openings. Without proper water diversion, rain would run down the face of the building and potentially penetrate under the door. We addressed this by specifying thicker bottom seals that created positive water exclusion even without the standard drip ledge detail.

This project shows why we stress finding potential “gotchas” early in the specs. We caught the drip ledge issue during the plan review. By adjusting the door specs, we avoided a costly field fix or even worse, water intrusion after installation.

Disadvantages of Insulated Sectional Doors

Similar Pricing to High-Performance Doors: The price range of $3,500 to $5,000 is very close to that of high-performance doors. For applications where energy efficiency isn’t key, a high-performance door can provide better value. It offers greater durability and a longer cycle life.

Heavier Door Weight: The Intellicore insulation adds weight compared to non-insulated doors. Heavier doors need stronger torsion springs, hardware, and operators. This can raise installation costs and make the process more complex.

ROI Depends on Climate Control: For non-climate-controlled facilities—like unheated warehouses or outdoor storage—the insulation helps very little. The investment only makes sense where temperature control matters.

Limited Security Enhancement: While the insulated construction is stronger than hollow doors, insulated sectional doors don’t provide meaningfully better security than non-insulated sectional doors. For maximum security, rolling steel doors remain superior.

Pricing Factors for Insulated Sectional Doors

The $3,500-$5,000 range for a 10’x10′ insulated door reflects:

-

Insulation type and R-value: Polyurethane (like Intellicore) costs more than polystyrene; higher R-values increase cost

-

Steel gauge: 27-gauge is standard; 24-gauge costs more but provides better impact resistance

-

Panel design: Stucco embossed is standard; alternative patterns or smooth surfaces may affect pricing

-

Color: Standard white is included; custom colors add cost

-

Window configuration: Solid panels are base price; window sections increase cost

-

Track type: Standard lift is included; high-lift or vertical-lift configurations add cost

-

Hardware cycle rating: 25,000-cycle components are standard; 50,000 or 100,000-cycle upgrades available

When to Choose Insulated Sectional Doors

Insulated sectional doors are the right choice when:

-

Your facility is climate-controlled and energy costs matter

-

Temperature-sensitive products or processes require stable conditions

-

Worker comfort near door openings is a priority

-

Condensation prevention is important

-

You want to reduce HVAC system load and extend equipment life

-

Noise reduction provides operational or neighbor-relations benefits

-

The facility pursues LEED certification or green building standards

In North Texas, quality insulated doors for climate-controlled facilities cost a bit more, but they usually pay for themselves in energy savings within 3-5 years. This makes them a wise choice during the specification process.

Door Type #5: Rolling Sheet Doors

Representative Product: Clopay 160C Heavy Duty Typical 10’x10′ Investment: $2,500 – $3,750 (door only, excluding tax and installation)

What Are Rolling Sheet Doors?

Rolling sheet doors represent the economy tier of commercial coiling doors. These doors offer basic security and weather protection. They are affordable, making them great for budget-friendly projects or when simple functionality is enough. The steel slat design coils into a compact barrel above the opening. This setup needs little headroom, just like commercial-grade rolling service doors.

The Clopay 160C fits this category well. It has a 12″ coil diameter and a corrugated panel design. The construction is non-insulated. It operates manually with a ratchet spring tension assembly. It also includes basic draft stop seals.

Best Applications

Rolling sheet doors serve facilities where value and basic functionality are priorities:

-

Self-storage facilities: Individual tenant units requiring basic security

-

Mini-warehouses: Interior partition doors separating storage areas

-

Commercial storage rooms: Back-of-house storage in retail or office buildings

-

Equipment enclosures: Protecting mechanical equipment or utility areas

-

Covered loading areas: Semi-protected docks or covered bays

-

Budget-constrained projects: New construction or renovation where cost control is critical

Key Features

Corrugated Panel Design: The traditional corrugated pattern provides good structural strength through the ribbed geometry. While not as refined aesthetically as flat panels, corrugated construction is time-tested and economical to manufacture.

12″ Coil Configuration: The compact coil size minimizes headroom requirements, though larger doors may require larger coils. The simple coiling mechanism is straightforward and reliable.

Manual Operation: The ratchet spring tension assembly allows manual push-up operation for doors up to moderate sizes. While manual operation requires physical effort, it eliminates operator costs and power requirements.

Draft Stop Seals: Basic weather sealing prevents most wind and rain intrusion, though not to the same standard as fully sealed commercial-grade doors.

Non-Insulated Construction: Single-layer steel slats provide no thermal resistance. This construction is appropriate for unconditioned spaces or applications where temperature control isn’t required.

Advantages of Rolling Sheet Doors

Most Economical Option: The $2,500-$3,750 price point for a 10’x10′ door makes rolling sheet doors the most budget-friendly commercial overhead door option. For projects with tight budgets or where basic features work, the value is clear.

Simple and Reliable: With fewer components and straightforward construction, rolling sheet doors have less that can go wrong. The simplicity translates to reliability in appropriate applications.

No Power Required: Manual operation eliminates the need for electrical power at the door location, simplifying installation and reducing costs. For remote locations or temporary structures, this can be a significant advantage.

Disadvantages of Rolling Sheet Doors

Limited Durability: The lighter construction and cheaper parts lead to a shorter service life than commercial-grade rolling doors. Expect 8-12 years rather than 15-20+ years from heavier-duty options.

Manual Operation Limitations: Pushing up a door manually becomes impractical for larger sizes or high-frequency use. Most operators won’t want to manually operate a 12’x12′ rolling door 20 times daily.

No Insulation: For any application requiring temperature control, rolling sheet doors are inappropriate. The single-layer construction provides essentially zero thermal resistance.

Basic Weather Sealing: Draft stop seals work for many uses, but they can’t match the full weather protection of commercial-grade doors. These doors have complete perimeter sealing systems.

Industrial Appearance: The corrugated design and economy finish are purely functional. For customer-facing applications or facilities where appearance matters, rolling sheet doors don’t deliver refined aesthetics.

Lower Cycle Rating: Economy doors typically warrant 10,000-15,000 cycles rather than the 25,000-50,000+ cycles of commercial-grade products. High-traffic applications will wear out these doors prematurely.

Upgrade Costs Can Add Up: Want an operator? Chain hoist? Custom color? Each upgrade brings the total cost closer to commercial-grade rolling service doors, potentially eliminating the initial cost advantage.

When Rolling Sheet Doors Make Sense

Rolling sheet doors are the right choice when:

-

Budget is the primary decision driver

-

The application is low-frequency (2-5 cycles daily)

-

Temperature control isn’t required

-

Basic security and weather protection suffice

-

Headroom is severely limited

-

Power isn’t available at the door location

-

The door is interior or hidden from view

-

You’re specifying for self-storage or mini-warehouse tenant units

When to Spend More for Commercial-Grade Doors

Consider upgrading to rolling service doors or sectional doors when:

-

The facility requires a professional appearance

-

Daily cycle count exceeds 10-15 operations

-

Climate control is needed

-

You want to minimize maintenance and maximize service life

-

The door location is visible or customer-facing

-

Total cost of ownership matters more than initial investment

Making the Right Choice for Your Facility

To choose the best commercial overhead door for your project, consider these five types. They range from $2,500 to $11,500 for a standard 10’x10′ opening. Here’s how to decide:

Decision Framework

Use this framework to narrow your options:

Start with Usage Frequency:

-

2-5 cycles/day → Rolling sheet doors or standard sectional doors

-

10-20 cycles/day → Insulated sectional, high-performance, or rolling service doors

-

20+ cycles/day → High-performance or commercial rolling service doors

Consider Environment:

-

Climate-controlled facility → Insulated sectional or high-performance doors

-

Unconditioned space → Rolling sheet, rolling service, or non-insulated sectional

-

Extreme weather exposure → High-performance or rolling service doors with enhanced sealing

Evaluate Security Requirements:

-

Basic security → Rolling sheet or sectional doors adequate

-

Commercial security → Rolling service or heavy-duty sectional doors

-

Maximum security → Commercial rolling service doors

Factor in Aesthetics:

-

Customer-facing/visible → Full-view doors or high-end sectional doors

-

Industrial/back-of-house → Any door type appropriate for function

-

Budget facility → Rolling sheet or economy sectional doors

Account for Space Constraints:

-

Limited headroom → Rolling doors (sheet or service grade)

-

Standard clearance → Sectional or rolling doors both work

-

Forklift traffic requiring high-lift → Rolling or sectional with high-lift tracks

Common Specification Scenarios

New Distribution Center:

-

Loading Dock Doors: Insulated sectional or high-performance doors for climate control and durability.

-

Interior Warehouse Partition Doors: Rolling service doors for security and space efficiency.

Auto Dealership:

-

Showroom service drive-through: Full-view doors for better aesthetics and visibility.

-

Service bay doors: Insulated sectional doors help with temperature control and look good.

-

Back-of-house storage: Rolling service doors offer security and value.

Self-Storage Facility:

-

Individual tenant units: Rolling sheet doors for economy and adequate security.

-

Manager’s office/main building: An insulated sectional door for improved appearance and comfort.

Manufacturing Facility:

-

Production area separation: High-performance or insulated sectional doors for climate control and durability.

-

Shipping/receiving: Rolling service or insulated sectional doors for security and weather protection.

-

Equipment storage: Rolling sheet doors for economy and basic security.

Beyond the Door: Important Considerations

Track Configuration: Many North Texas facilities specify high-lift or vertical-lift track systems to provide clearance for forklifts and machinery. This affects both sectional and rolling door installations, adding to the overall project cost.

Operator Selection: Manual operation, chain hoist, or motorized operators significantly impact both initial cost and operational efficiency. High-traffic applications justify the use of motor operators, despite the added expense.

Building Code Compliance: Job-specific requirements vary. Work with your door supplier to ensure specifications meet all applicable codes.

Lead Times: Commercial overhead doors typically require 2-4 weeks for delivery after the order is placed. Plan accordingly to avoid project delays. Once doors arrive, most installations can commence within the same week.

Installation Complexity: Steel and masonry openings are more complex (and costly) to frame than wood openings. Coordinate with your door supplier during the planning phase to identify any special requirements.

Working With Doorvana: Our Approach to Commercial Door Projects

At Doorvana, we believe in radical transparency. This article demonstrates our commitment to addressing questions that other door companies overlook. We’ll have honest discussions about pricing, product limitations, and when more affordable options might meet your needs just as well.

Our Process

1. Request for Proposal (RFP) Review: When we receive your RFP, we carefully evaluate the plan set, noting door sizes, quantities, specifications, and any details that might present installation challenges. We ask questions early—before bidding. This helps us ensure that our proposal accurately reflects the actual scope of work.

2. Accurate Bidding: We provide detailed proposals that break down door specifications, operators, track systems, and any options or upgrades. Our goal is accuracy, not being the lowest number on the bid sheet. Unrealistically low bids cause problems for everyone, especially when change orders pile up during installation.

3. Field Verification: Once approved, we field-verify critical dimensions and installation conditions. This step identifies discrepancies between plans and actual conditions before ordering doors. This helps avoid costly delays or changes.

4. Order Placement and Tracking: We place orders with manufacturers and actively track delivery status, communicating progress to project managers throughout the process. Typical delivery is 2-4 weeks, depending on door type and specifications.

5. Installation Coordination: We team up with project managers. We schedule installation based on delivery dates and when the project is ready. Our in-house teams have the best tools and equipment. Our technicians also get ongoing training to meet manufacturer standards and best practices.

6. **Service After the Sale:** We offer a one-year limited labor warranty on all installs. This ensures doors meet manufacturer specs and are free from defects. Beyond warranty, we offer ongoing maintenance agreements and on-demand service for the life of your doors.

Why Clients Choose Doorvana

Responsive: We answer calls, respond to emails, and meet commitments. When you have a question about your project, you’ll get a prompt, helpful answer.

Accurate: Our proposals reflect reality, not wishful thinking. We identify potential issues early and provide solutions before they become problems.

Helpful: We don’t just take orders. We help you choose the right doors for your needs. Sometimes that means recommending less expensive options when they’ll serve your needs adequately.

Our Service Area

We’re located in North Texas. We serve the Dallas-Fort Worth area and nearby regions. For larger projects, we’re willing to travel beyond our primary service area. If your project is located outside of North Texas, please get in touch with us to discuss options.

Brands We Offer

We install commercial overhead doors from:

-

Clopay

-

Amarr

-

Janus

-

Cornell

-

Hörmann

This multi-manufacturer approach lets us choose the best product for each application. We don’t have to fit every project into just one brand’s line.

Licensing and Insurance

We maintain appropriate licensing and insurance for commercial door installation. If your project has specific insurance or bonding requirements, let us know during the bidding process and we’ll ensure compliance before work commences.

Thank You for Reading

If you’ve made it this far, you’re clearly serious about making an informed decision on commercial overhead doors for your project. Thank you for investing your time in understanding these important building components.

We created this comprehensive guide because we believe transparency builds trust. Other door companies might give you glossy brochures and vague pricing. We’d rather give you the real information you need to specify the right doors for your applications—even if that means recommending less expensive options when they’ll serve your needs adequately.

What Makes Doorvana Different

We’re not the biggest door company in North Texas, and we’re not trying to be. We’re building something different: a team of high-performing individuals who care more, respond faster, and deliver more accurate work than our competitors.

People buy from people. At Doorvana, we attract professionals who take pride in their work, answer their phones promptly, arrive on time, and solve problems rather than creating them. That’s the Doorvana difference.

Ready to Discuss Your Commercial Door Project?

Whether you’re a commercial general contractor preparing to bid a project, a property developer planning a new facility, or a facility manager evaluating door replacement options, we’re here to help.

Get Started Today

Request a Proposal:

Have plans and specifications ready? Submit your RFP through our commercial door services page or request a quote and we’ll provide a detailed, accurate proposal typically within 1-3 business days.

Schedule a Consultation:

Need help specifying the right doors before plans are finalized? Want to discuss options for an existing facility? Contact us to schedule a consultation. We’ll evaluate your requirements, visit your site if needed, and provide recommendations based on your specific application and budget.

Add Us to Your Approved Vendor List:

Many general contractors and developers maintain approved vendor lists for trades. If you’ve been impressed by our approach and want to establish a working relationship for future projects, we’d be honored to be added to your list.

Explore More Resources:

Visit our blog for additional articles on commercial and residential overhead door topics, or browse our garage door products to see specific models and options.

Contact Information

Email: [email protected]

Service Area Details: View our complete service area

Call US: 817-500-5988

What Happens Next?

- You contact us with your project details or RFP

- We review your requirements and ask any clarifying questions

- We provide an accurate proposal addressing all specifications

- You approve, and we field-verify details before ordering

- We order, track, and communicate delivery status

- We install on schedule with our trained technicians

- You receive warranty protection and ongoing service support

We make the commercial overhead door specification and installation process as straightforward as possible. No surprises, no excuses—just responsive, accurate, helpful service that gets your project completed on time.

About the Author

Bobby Vickers, MBA, is the founder of Doorvana, bringing five years of commercial overhead door experience to projects in North Texas. His approach emphasizes responsiveness, accuracy, and identifying potential installation challenges early in the project lifecycle, thereby preventing costly delays and change orders.

“My job is to make things easy for general contractors and developers,” Bobby explains. “That means answering questions honestly, delivering accurate bids, and catching problems before doors are ordered. When you work with Doorvana, you’re working with people who care about getting it right.”

Bobby’s commitment to the “They Ask You Answer” content marketing methodology reflects his belief that transparency builds lasting business relationships. “If we can’t be honest about pricing, product limitations, and when cheaper options might work just fine, then we’re not really helping our clients make good decisions.”

When he’s not specifying commercial overhead doors, Bobby focuses on building a team culture that attracts high-performing individuals who share Doorvana’s values of responsiveness, accuracy, and genuine care for client success.